Sungunulani Makandulo a Polima Sefa ya High viscosity Substances Sefa

Sungunulani Sefa ya Makandulo a Polymer

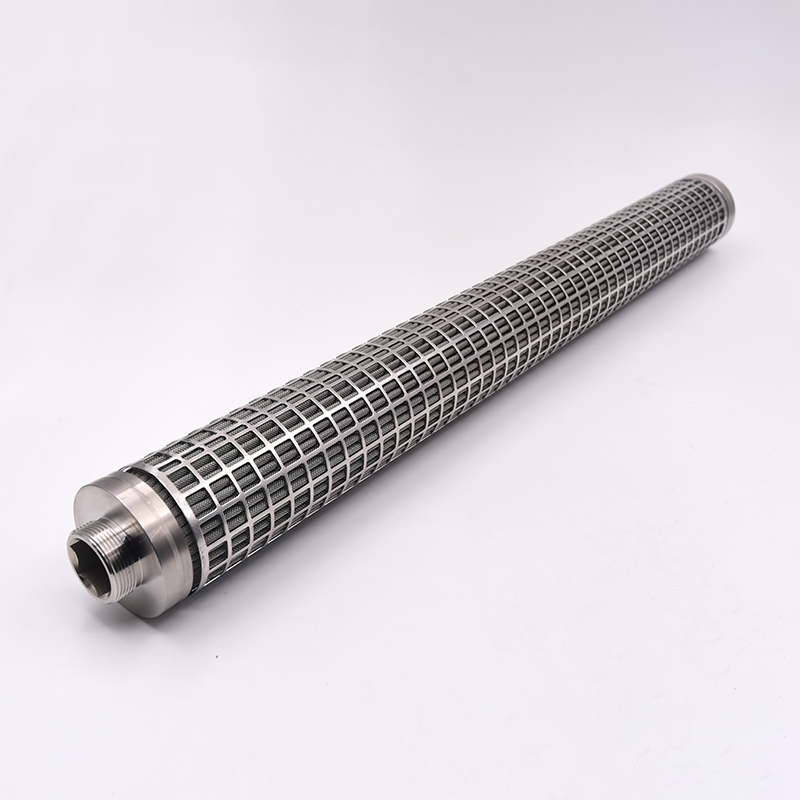

Melt filter element ndi chinthu chazitsulo zonse chowotcherera ndi argon arc welding.Zosefera zosanjikiza zimatengera njira yopindika yamitundu ingapo, ndikugawa kukula kwa pore ndikuwonjezera malo osefa.Chosefera chopindika chachitsulo chimapangidwa ndi chitsulo chosapanga dzimbiri, chopanda kutayikira kapena kukhetsa kwapakati.M'malo ovuta kwambiri, fyuluta yachitsulo chosapanga dzimbiri imatengera mapangidwe a mafupa.Chigoba chamkati ndi chakunja chimathandizira kwambiri kukana kwachitsulo cha pleated filter element.Chosefera chachikulu cha Pleated Filter makamaka chimagwiritsa ntchito zida ziwiri: waya wachitsulo chosapanga dzimbiri ndi chitsulo chosapanga dzimbiri Sintered CHIKWANGWANI.Mawaya achitsulo chosapanga dzimbiri amalukidwa kuchokera ku waya wachitsulo chosapanga dzimbiri.Fyuluta yake yosalala imakhala ndi ma pores osalala, kuyeretsa kosavuta, kukana kutentha kwambiri, kukana dzimbiri, ma waya osatsika, komanso kusefa kwakutali.Chitsulo chosapanga dzimbiri sintered CHIKWANGWANI ndi porous deep sefa zinthu zopangidwa ndi zitsulo zosapanga dzimbiri sintered pa kutentha kwambiri.Fyuluta yake yotsekemera imakhala ndi mawonekedwe a porosity apamwamba, mpweya wabwino wodutsa mpweya, mphamvu yamphamvu yogwira dothi, komanso mphamvu yosinthika.

Sungunulani fyuluta ndi chipangizo chosefera chomwe chimagwiritsidwa ntchito kwambiri pamakampani opanga mankhwala opangira ma polima osungunuka ndi zinthu zina zowoneka bwino kwambiri.Ntchito yake ndikuchotsa zodetsa zolimba monga particles carbonized ndi oxides zitsulo mu kusungunula, kusintha chiyero cha kusungunula, kupereka zipangizo zoyenera zopangira njira zotsika, ndikuonetsetsa kuti fyuluta yosungunuka ikugwira ntchito bwino.

Makhalidwe Aukadaulo

1. Kugonjetsedwa ndi kutentha kwakukulu, kuthamanga kwakukulu ndi dzimbiri za mankhwala.

2. Kupuma kwabwino kwambiri, mphamvu yaikulu yogwiritsira ntchito dothi, mphamvu zambiri, kusindikiza bwino, moyo wautali, ndipo akhoza kutsukidwa ndi kugwiritsidwa ntchito mobwerezabwereza.

3. Malo opindidwa fyuluta ndi nthawi 3-5 kuposa mtundu wa cylindrical.

4. Kutentha kwa ntchito: -60-500 ℃.

5. Kuthamanga kwakukulu kosiyana komwe fyuluta ingathe kupirira: 10MPa.

Ma Parameters Ogwiritsa Ntchito Pagulu

1. Kupanikizika kwa ntchito: 30Mpa.

2. Kutentha kwa ntchito: 300 ℃.

3. Dothi kugwira mphamvu: 16.9 ~ 41mg/cm².

Njira Yolumikizira Zinthu

Mawonekedwe okhazikika (monga 222, 220, 226) kulumikizana mwachangu kwa mawonekedwe, kulumikizana kwa ulusi, kulumikizana kwa flange, kulumikizana kwa ndodo, mawonekedwe apadera mwamakonda.

Malo Ofunsira

1. Petrochemical: Kuyeretsa, kupanga mankhwala ndi kulekanitsa ndi kubwezeretsa zinthu zapakati.

2. Metallurgy: amagwiritsidwa ntchito posefera makina a hydraulic a mphero zogubuduza ndi makina opitilira aponyera.

3. Zovala: Kuyeretsedwa ndi kusefa yunifolomu ya polyester kusungunuka panthawi yojambula.

4. Zamagetsi ndi mankhwala: Kuchiza ndi kusefera kwa reverse osmosis madzi ndi deionized madzi, pre-mankhwala ndi kusefera madzi oyeretsa ndi shuga.

5. Mphamvu yotentha ndi mphamvu ya nyukiliya: kuyeretsedwa kwa machitidwe odzola mafuta, machitidwe oyendetsa liwiro, machitidwe oyendetsa gasi ndi ma boilers, kuyeretsa mapampu amadzimadzi, mafani ndi machitidwe ochotsera fumbi.

Zambiri Zogulitsa